Brunswick Kit Kat Matte White Tile

Product Details

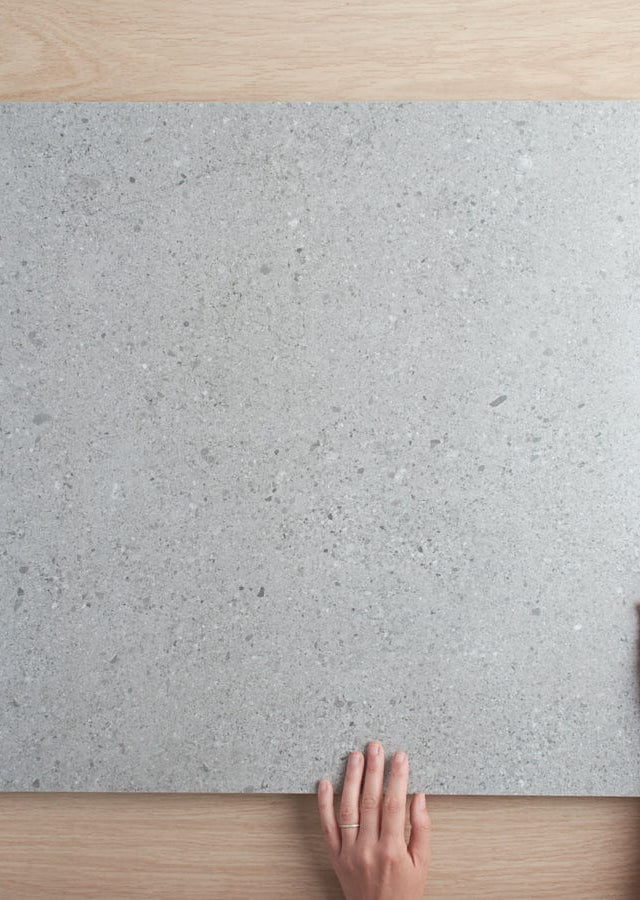

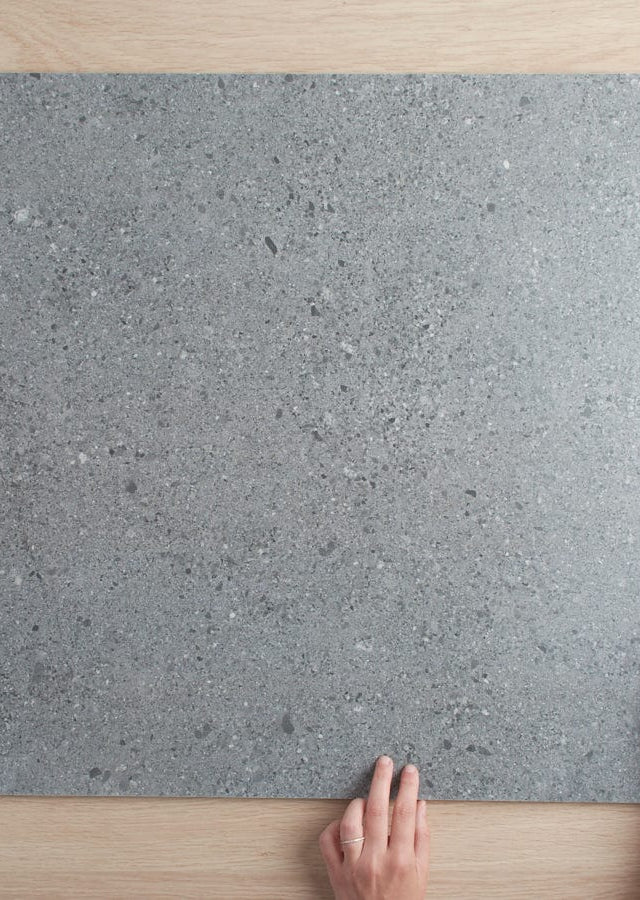

Suggested Grout Colour Mapei Silver Grey

Suggested Silicone Silver Grey

Tile Thickness 6mm

Matt Finish

Sheet size 296x300mm / Each piece 145x22mm

Made of porcelain

Easy to clean and maintain

Suitable for use on and Walls only

Size – Tiles are displayed as their ‘nominal size’ for simplicity. Eg 300x600mm. The actual tile size may vary slightly from this depending on manufacturer. Eg 297x601mm. Please factor in actual size when figuring out if different tile grout joints or patterns will line up.

Batching – The colour, shade, size and texture of tiles can vary from batch to batch. If you are placing an additional order to match with existing tiles, please contact sales@tilecloud.com.au to make sure the batch is the same.

Samples – Final products may exhibit variation from sample. Variation in colour, shade, texture and pattern between production runs may occur but will be within manufacturing standards.